Our Three Step Process

December 17, 2024

The NorthnStar Way: A Step-by-Step Guide to Our Product Design Process

Our Three Step Process

December 17, 2024

The NorthnStar Way: A Step-by-Step Guide to Our Product Design Process

Discover how NorthnStar transforms ideas into successful products through our comprehensive, collaborative, and proven product design process. This article provides an in-depth look at each stage, highlighting our expertise and commitment to client success.

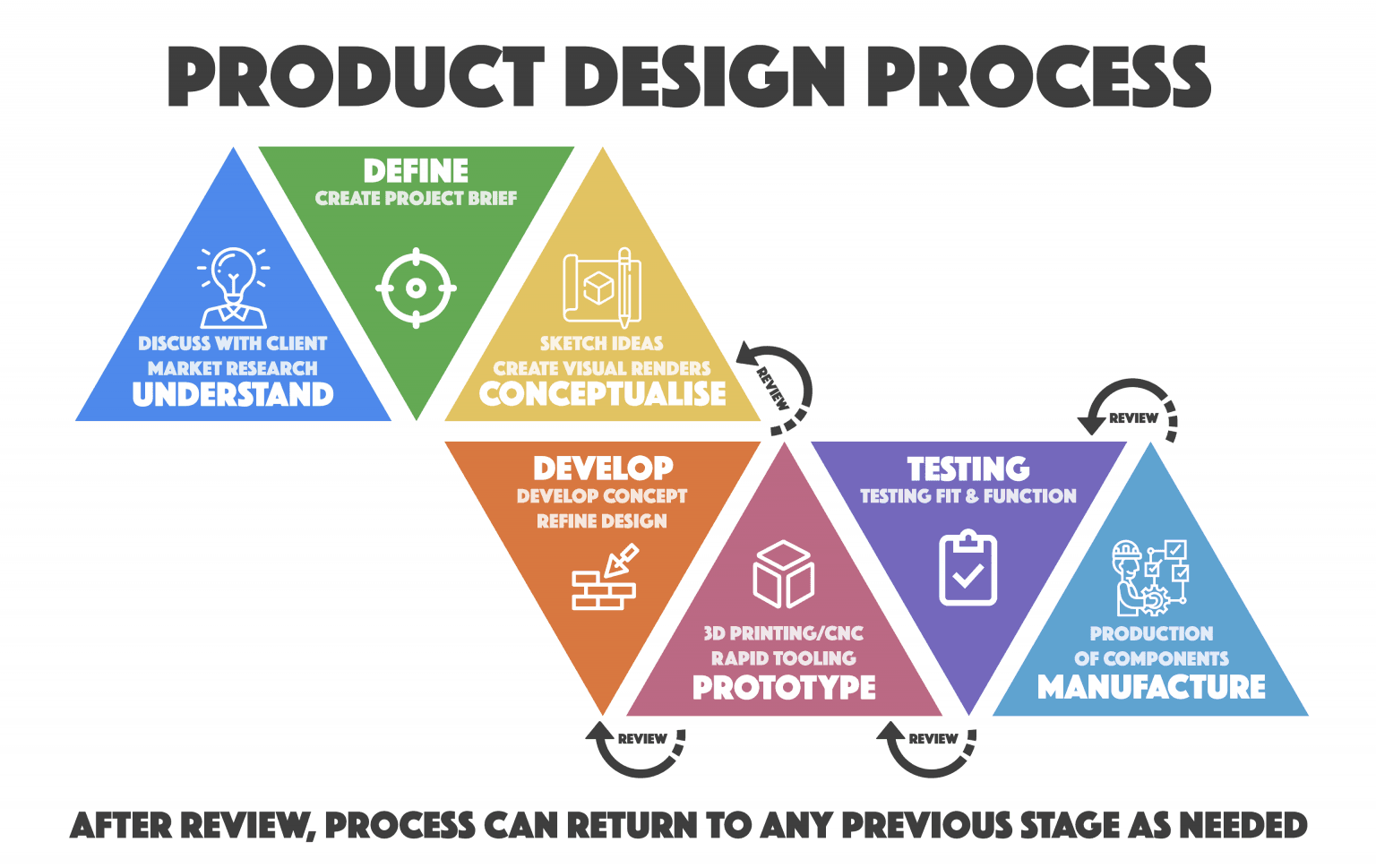

What does it take to transform a simple idea into a successful product? At NorthnStar, we've honed a comprehensive product design process that combines innovation, collaboration, and expertise. Let's take a deep dive into the NorthnStar Way and explore how our step-by-step approach turns visions into reality.

At NorthnStar, we believe that every great product starts with a great process. Many clients have approached us with brilliant ideas but faced challenges in bringing them to fruition. They struggled with unclear development paths, resource constraints, and navigating complex market demands. Recognizing these hurdles, we've developed a structured yet flexible product design process that guides projects from concept to completion. This article outlines the NorthnStar Way, providing insights into each stage of our methodology to help you understand how we make product dreams come true.

Why a Structured Product Design Process Matters

A well-defined product design process is crucial for:

Efficiency: Streamlining workflows to save time and resources.

Quality Assurance: Ensuring that products meet high standards and customer expectations.

Risk Mitigation: Identifying and addressing potential issues early in the development cycle.

Innovation Encouragement: Fostering creativity within a structured framework.

Client Collaboration: Facilitating clear communication and alignment with client goals.

Statistic:

According to The Project Management Institute, organizations with standardized project management practices see a 28% improvement in project performance.

The NorthnStar Way: Our Step-by-Step Product Design Process

1. Discovery and Ideation

Objective: Understand the client's vision, market needs, and project feasibility.

Actions:

Client Consultation:

Engage in in-depth discussions to grasp the idea, objectives, and expectations.

Establish project scope, timelines, and resource requirements.

Market Research:

Analyze industry trends, target audience, and competitor products.

Identify opportunities and potential challenges in the market.

Feasibility Study:

Assess technical, financial, and regulatory feasibility.

Provide recommendations and insights to refine the concept.

Case Study:

A startup approached us with an idea for a smart wearable device aimed at health monitoring. They lacked market insights and technical expertise. Through our discovery phase, we identified a niche market segment and refined the product concept to align with market demands.

Key Takeaways:

Early collaboration clarifies vision and sets a strong foundation.

Market insights guide strategic decision-making.

2. Concept Development

Objective: Transform the refined idea into tangible concepts.

Actions:

Brainstorming Sessions:

Facilitate creative workshops with cross-functional teams.

Generate multiple design concepts and solutions.

Concept Sketching and Modeling:

Create initial sketches and 3D models to visualize ideas.

Explore different design directions and features.

Concept Evaluation:

Assess concepts based on criteria such as functionality, aesthetics, user experience, and feasibility.

Select the most promising concepts for further development.

Key Takeaways:

Diverse perspectives enhance creativity.

Visual representations aid in evaluating and communicating ideas.

3. Design and Engineering

Objective: Develop detailed designs and engineering plans.

Actions:

Industrial Design:

Refine the product's form, ergonomics, and aesthetics.

Ensure the design aligns with brand identity and user preferences.

Mechanical and Electrical Engineering:

Develop detailed engineering drawings and specifications.

Integrate components, materials, and technologies.

Simulation and Analysis:

Use simulations (e.g., FEA, CFD) to test structural integrity and performance.

Optimize designs for efficiency and functionality.

Key Takeaways:

Integrating design and engineering ensures coherence between form and function.

Simulations reduce risks and improve design quality.

4. Prototyping

Objective: Create physical prototypes to validate designs.

Actions:

Rapid Prototyping:

Utilize 3D printing, CNC machining, or other methods to produce prototypes quickly.

Build functional and appearance models.

Testing and Evaluation:

Conduct tests for functionality, usability, and durability.

Gather feedback from stakeholders and potential users.

Iterative Refinement:

Identify issues and implement improvements.

Repeat prototyping cycles as necessary.

Case Study:

For the smart wearable device, we developed several prototypes, testing for comfort, sensor accuracy, and user interface. User feedback led to ergonomic adjustments and software enhancements.

Key Takeaways:

Prototyping validates assumptions and identifies areas for improvement.

Iterative refinement leads to a superior final product.

5. Design for Manufacturing (DFM) and Documentation

Objective: Prepare the product for mass production.

Actions:

Design Optimization:

Adjust designs to simplify manufacturing and reduce costs.

Select appropriate materials and processes.

Manufacturing Collaboration:

Work with manufacturers to ensure design compatibility with production capabilities.

Address potential production challenges early.

Technical Documentation:

Create detailed drawings, specifications, and assembly instructions.

Document quality standards and testing protocols.

Key Takeaways:

Early consideration of manufacturing factors prevents costly changes later.

Clear documentation facilitates efficient production and quality control.

6. Production and Quality Assurance

Objective: Oversee the initial production and ensure quality standards are met.

Actions:

Pilot Production Run:

Conduct a small-scale production to test manufacturing processes.

Identify and resolve any production issues.

Quality Control Implementation:

Establish inspection criteria and testing procedures.

Monitor production for consistency and adherence to standards.

Supplier and Supply Chain Management:

Coordinate with suppliers for components and materials.

Ensure timely delivery and quality of supplies.

Key Takeaways:

Pilot runs reduce risks before full-scale production.

Rigorous quality assurance maintains product integrity and brand reputation.

7. Launch Support and Post-Launch Services

Objective: Facilitate a successful product launch and provide ongoing support.

Actions:

Marketing and Branding Assistance:

Provide assets and insights for marketing campaigns.

Ensure product packaging and branding align with design.

Regulatory Compliance:

Assist with certifications and adherence to industry regulations.

Prepare necessary documentation for legal compliance.

Post-Launch Monitoring:

Collect user feedback and performance data.

Support updates and improvements based on real-world use.

Case Study:

After launching the smart wearable device, we continued to support the client by analyzing user data and implementing software updates, enhancing user satisfaction and product performance.

Key Takeaways:

Ongoing support enhances product success and customer satisfaction.

Monitoring post-launch performance informs future iterations.

Challenges and How We Overcome Them

1. Communication Gaps

Challenge: Misalignment between client expectations and project outcomes.

Solution: Maintain transparent, regular communication and involve clients throughout the process.

2. Resource Constraints

Challenge: Limited budgets and tight timelines.

Solution: Prioritize tasks, optimize processes, and leverage efficient technologies.

3. Technical Complexities

Challenge: Integrating advanced technologies or overcoming engineering hurdles.

Solution: Utilize our team's expertise and innovative problem-solving approaches.

Why Choose the NorthnStar Way

Holistic Approach: We cover every aspect of product development, ensuring a seamless transition from concept to market.

Collaborative Partnership: Clients are integral to our process, fostering alignment and satisfaction.

Expert Team: Our multidisciplinary team brings together designers, engineers, strategists, and more.

Proven Track Record: Success stories across industries demonstrate our capability to deliver exceptional products.

Conclusion

The journey from an idea to a market-ready product is complex, but with a structured process and the right partner, it's achievable and rewarding. The NorthnStar Way embodies our commitment to excellence, innovation, and client success.

At NorthnStar, we're passionate about bringing your visions to life. Let our step-by-step product design process guide you on the path to success.

Ready to embark on your product development journey with us? Contact NorthnStar today, and let's create something extraordinary together.

What does it take to transform a simple idea into a successful product? At NorthnStar, we've honed a comprehensive product design process that combines innovation, collaboration, and expertise. Let's take a deep dive into the NorthnStar Way and explore how our step-by-step approach turns visions into reality.

At NorthnStar, we believe that every great product starts with a great process. Many clients have approached us with brilliant ideas but faced challenges in bringing them to fruition. They struggled with unclear development paths, resource constraints, and navigating complex market demands. Recognizing these hurdles, we've developed a structured yet flexible product design process that guides projects from concept to completion. This article outlines the NorthnStar Way, providing insights into each stage of our methodology to help you understand how we make product dreams come true.

Why a Structured Product Design Process Matters

A well-defined product design process is crucial for:

Efficiency: Streamlining workflows to save time and resources.

Quality Assurance: Ensuring that products meet high standards and customer expectations.

Risk Mitigation: Identifying and addressing potential issues early in the development cycle.

Innovation Encouragement: Fostering creativity within a structured framework.

Client Collaboration: Facilitating clear communication and alignment with client goals.

Statistic:

According to The Project Management Institute, organizations with standardized project management practices see a 28% improvement in project performance.

The NorthnStar Way: Our Step-by-Step Product Design Process

1. Discovery and Ideation

Objective: Understand the client's vision, market needs, and project feasibility.

Actions:

Client Consultation:

Engage in in-depth discussions to grasp the idea, objectives, and expectations.

Establish project scope, timelines, and resource requirements.

Market Research:

Analyze industry trends, target audience, and competitor products.

Identify opportunities and potential challenges in the market.

Feasibility Study:

Assess technical, financial, and regulatory feasibility.

Provide recommendations and insights to refine the concept.

Case Study:

A startup approached us with an idea for a smart wearable device aimed at health monitoring. They lacked market insights and technical expertise. Through our discovery phase, we identified a niche market segment and refined the product concept to align with market demands.

Key Takeaways:

Early collaboration clarifies vision and sets a strong foundation.

Market insights guide strategic decision-making.

2. Concept Development

Objective: Transform the refined idea into tangible concepts.

Actions:

Brainstorming Sessions:

Facilitate creative workshops with cross-functional teams.

Generate multiple design concepts and solutions.

Concept Sketching and Modeling:

Create initial sketches and 3D models to visualize ideas.

Explore different design directions and features.

Concept Evaluation:

Assess concepts based on criteria such as functionality, aesthetics, user experience, and feasibility.

Select the most promising concepts for further development.

Key Takeaways:

Diverse perspectives enhance creativity.

Visual representations aid in evaluating and communicating ideas.

3. Design and Engineering

Objective: Develop detailed designs and engineering plans.

Actions:

Industrial Design:

Refine the product's form, ergonomics, and aesthetics.

Ensure the design aligns with brand identity and user preferences.

Mechanical and Electrical Engineering:

Develop detailed engineering drawings and specifications.

Integrate components, materials, and technologies.

Simulation and Analysis:

Use simulations (e.g., FEA, CFD) to test structural integrity and performance.

Optimize designs for efficiency and functionality.

Key Takeaways:

Integrating design and engineering ensures coherence between form and function.

Simulations reduce risks and improve design quality.

4. Prototyping

Objective: Create physical prototypes to validate designs.

Actions:

Rapid Prototyping:

Utilize 3D printing, CNC machining, or other methods to produce prototypes quickly.

Build functional and appearance models.

Testing and Evaluation:

Conduct tests for functionality, usability, and durability.

Gather feedback from stakeholders and potential users.

Iterative Refinement:

Identify issues and implement improvements.

Repeat prototyping cycles as necessary.

Case Study:

For the smart wearable device, we developed several prototypes, testing for comfort, sensor accuracy, and user interface. User feedback led to ergonomic adjustments and software enhancements.

Key Takeaways:

Prototyping validates assumptions and identifies areas for improvement.

Iterative refinement leads to a superior final product.

5. Design for Manufacturing (DFM) and Documentation

Objective: Prepare the product for mass production.

Actions:

Design Optimization:

Adjust designs to simplify manufacturing and reduce costs.

Select appropriate materials and processes.

Manufacturing Collaboration:

Work with manufacturers to ensure design compatibility with production capabilities.

Address potential production challenges early.

Technical Documentation:

Create detailed drawings, specifications, and assembly instructions.

Document quality standards and testing protocols.

Key Takeaways:

Early consideration of manufacturing factors prevents costly changes later.

Clear documentation facilitates efficient production and quality control.

6. Production and Quality Assurance

Objective: Oversee the initial production and ensure quality standards are met.

Actions:

Pilot Production Run:

Conduct a small-scale production to test manufacturing processes.

Identify and resolve any production issues.

Quality Control Implementation:

Establish inspection criteria and testing procedures.

Monitor production for consistency and adherence to standards.

Supplier and Supply Chain Management:

Coordinate with suppliers for components and materials.

Ensure timely delivery and quality of supplies.

Key Takeaways:

Pilot runs reduce risks before full-scale production.

Rigorous quality assurance maintains product integrity and brand reputation.

7. Launch Support and Post-Launch Services

Objective: Facilitate a successful product launch and provide ongoing support.

Actions:

Marketing and Branding Assistance:

Provide assets and insights for marketing campaigns.

Ensure product packaging and branding align with design.

Regulatory Compliance:

Assist with certifications and adherence to industry regulations.

Prepare necessary documentation for legal compliance.

Post-Launch Monitoring:

Collect user feedback and performance data.

Support updates and improvements based on real-world use.

Case Study:

After launching the smart wearable device, we continued to support the client by analyzing user data and implementing software updates, enhancing user satisfaction and product performance.

Key Takeaways:

Ongoing support enhances product success and customer satisfaction.

Monitoring post-launch performance informs future iterations.

Challenges and How We Overcome Them

1. Communication Gaps

Challenge: Misalignment between client expectations and project outcomes.

Solution: Maintain transparent, regular communication and involve clients throughout the process.

2. Resource Constraints

Challenge: Limited budgets and tight timelines.

Solution: Prioritize tasks, optimize processes, and leverage efficient technologies.

3. Technical Complexities

Challenge: Integrating advanced technologies or overcoming engineering hurdles.

Solution: Utilize our team's expertise and innovative problem-solving approaches.

Why Choose the NorthnStar Way

Holistic Approach: We cover every aspect of product development, ensuring a seamless transition from concept to market.

Collaborative Partnership: Clients are integral to our process, fostering alignment and satisfaction.

Expert Team: Our multidisciplinary team brings together designers, engineers, strategists, and more.

Proven Track Record: Success stories across industries demonstrate our capability to deliver exceptional products.

Conclusion

The journey from an idea to a market-ready product is complex, but with a structured process and the right partner, it's achievable and rewarding. The NorthnStar Way embodies our commitment to excellence, innovation, and client success.

At NorthnStar, we're passionate about bringing your visions to life. Let our step-by-step product design process guide you on the path to success.

Ready to embark on your product development journey with us? Contact NorthnStar today, and let's create something extraordinary together.

Discover how NorthnStar transforms ideas into successful products through our comprehensive, collaborative, and proven product design process. This article provides an in-depth look at each stage, highlighting our expertise and commitment to client success.

What does it take to transform a simple idea into a successful product? At NorthnStar, we've honed a comprehensive product design process that combines innovation, collaboration, and expertise. Let's take a deep dive into the NorthnStar Way and explore how our step-by-step approach turns visions into reality.

At NorthnStar, we believe that every great product starts with a great process. Many clients have approached us with brilliant ideas but faced challenges in bringing them to fruition. They struggled with unclear development paths, resource constraints, and navigating complex market demands. Recognizing these hurdles, we've developed a structured yet flexible product design process that guides projects from concept to completion. This article outlines the NorthnStar Way, providing insights into each stage of our methodology to help you understand how we make product dreams come true.

Why a Structured Product Design Process Matters

A well-defined product design process is crucial for:

Efficiency: Streamlining workflows to save time and resources.

Quality Assurance: Ensuring that products meet high standards and customer expectations.

Risk Mitigation: Identifying and addressing potential issues early in the development cycle.

Innovation Encouragement: Fostering creativity within a structured framework.

Client Collaboration: Facilitating clear communication and alignment with client goals.

Statistic:

According to The Project Management Institute, organizations with standardized project management practices see a 28% improvement in project performance.

The NorthnStar Way: Our Step-by-Step Product Design Process

1. Discovery and Ideation

Objective: Understand the client's vision, market needs, and project feasibility.

Actions:

Client Consultation:

Engage in in-depth discussions to grasp the idea, objectives, and expectations.

Establish project scope, timelines, and resource requirements.

Market Research:

Analyze industry trends, target audience, and competitor products.

Identify opportunities and potential challenges in the market.

Feasibility Study:

Assess technical, financial, and regulatory feasibility.

Provide recommendations and insights to refine the concept.

Case Study:

A startup approached us with an idea for a smart wearable device aimed at health monitoring. They lacked market insights and technical expertise. Through our discovery phase, we identified a niche market segment and refined the product concept to align with market demands.

Key Takeaways:

Early collaboration clarifies vision and sets a strong foundation.

Market insights guide strategic decision-making.

2. Concept Development

Objective: Transform the refined idea into tangible concepts.

Actions:

Brainstorming Sessions:

Facilitate creative workshops with cross-functional teams.

Generate multiple design concepts and solutions.

Concept Sketching and Modeling:

Create initial sketches and 3D models to visualize ideas.

Explore different design directions and features.

Concept Evaluation:

Assess concepts based on criteria such as functionality, aesthetics, user experience, and feasibility.

Select the most promising concepts for further development.

Key Takeaways:

Diverse perspectives enhance creativity.

Visual representations aid in evaluating and communicating ideas.

3. Design and Engineering

Objective: Develop detailed designs and engineering plans.

Actions:

Industrial Design:

Refine the product's form, ergonomics, and aesthetics.

Ensure the design aligns with brand identity and user preferences.

Mechanical and Electrical Engineering:

Develop detailed engineering drawings and specifications.

Integrate components, materials, and technologies.

Simulation and Analysis:

Use simulations (e.g., FEA, CFD) to test structural integrity and performance.

Optimize designs for efficiency and functionality.

Key Takeaways:

Integrating design and engineering ensures coherence between form and function.

Simulations reduce risks and improve design quality.

4. Prototyping

Objective: Create physical prototypes to validate designs.

Actions:

Rapid Prototyping:

Utilize 3D printing, CNC machining, or other methods to produce prototypes quickly.

Build functional and appearance models.

Testing and Evaluation:

Conduct tests for functionality, usability, and durability.

Gather feedback from stakeholders and potential users.

Iterative Refinement:

Identify issues and implement improvements.

Repeat prototyping cycles as necessary.

Case Study:

For the smart wearable device, we developed several prototypes, testing for comfort, sensor accuracy, and user interface. User feedback led to ergonomic adjustments and software enhancements.

Key Takeaways:

Prototyping validates assumptions and identifies areas for improvement.

Iterative refinement leads to a superior final product.

5. Design for Manufacturing (DFM) and Documentation

Objective: Prepare the product for mass production.

Actions:

Design Optimization:

Adjust designs to simplify manufacturing and reduce costs.

Select appropriate materials and processes.

Manufacturing Collaboration:

Work with manufacturers to ensure design compatibility with production capabilities.

Address potential production challenges early.

Technical Documentation:

Create detailed drawings, specifications, and assembly instructions.

Document quality standards and testing protocols.

Key Takeaways:

Early consideration of manufacturing factors prevents costly changes later.

Clear documentation facilitates efficient production and quality control.

6. Production and Quality Assurance

Objective: Oversee the initial production and ensure quality standards are met.

Actions:

Pilot Production Run:

Conduct a small-scale production to test manufacturing processes.

Identify and resolve any production issues.

Quality Control Implementation:

Establish inspection criteria and testing procedures.

Monitor production for consistency and adherence to standards.

Supplier and Supply Chain Management:

Coordinate with suppliers for components and materials.

Ensure timely delivery and quality of supplies.

Key Takeaways:

Pilot runs reduce risks before full-scale production.

Rigorous quality assurance maintains product integrity and brand reputation.

7. Launch Support and Post-Launch Services

Objective: Facilitate a successful product launch and provide ongoing support.

Actions:

Marketing and Branding Assistance:

Provide assets and insights for marketing campaigns.

Ensure product packaging and branding align with design.

Regulatory Compliance:

Assist with certifications and adherence to industry regulations.

Prepare necessary documentation for legal compliance.

Post-Launch Monitoring:

Collect user feedback and performance data.

Support updates and improvements based on real-world use.

Case Study:

After launching the smart wearable device, we continued to support the client by analyzing user data and implementing software updates, enhancing user satisfaction and product performance.

Key Takeaways:

Ongoing support enhances product success and customer satisfaction.

Monitoring post-launch performance informs future iterations.

Challenges and How We Overcome Them

1. Communication Gaps

Challenge: Misalignment between client expectations and project outcomes.

Solution: Maintain transparent, regular communication and involve clients throughout the process.

2. Resource Constraints

Challenge: Limited budgets and tight timelines.

Solution: Prioritize tasks, optimize processes, and leverage efficient technologies.

3. Technical Complexities

Challenge: Integrating advanced technologies or overcoming engineering hurdles.

Solution: Utilize our team's expertise and innovative problem-solving approaches.

Why Choose the NorthnStar Way

Holistic Approach: We cover every aspect of product development, ensuring a seamless transition from concept to market.

Collaborative Partnership: Clients are integral to our process, fostering alignment and satisfaction.

Expert Team: Our multidisciplinary team brings together designers, engineers, strategists, and more.

Proven Track Record: Success stories across industries demonstrate our capability to deliver exceptional products.

Conclusion

The journey from an idea to a market-ready product is complex, but with a structured process and the right partner, it's achievable and rewarding. The NorthnStar Way embodies our commitment to excellence, innovation, and client success.

At NorthnStar, we're passionate about bringing your visions to life. Let our step-by-step product design process guide you on the path to success.

Ready to embark on your product development journey with us? Contact NorthnStar today, and let's create something extraordinary together.

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses