Our Three Step Process

June 11, 2024

From Sketch to Shelf: A Deep Dive into Packaging Design and Development

Our Three Step Process

June 11, 2024

From Sketch to Shelf: A Deep Dive into Packaging Design and Development

Explore the comprehensive process of packaging design and development, from initial concepts to final production. This article delves into real-world challenges, strategies, and best practices, highlighting NorthnStar's expertise in creating packaging that captivates consumers and enhances product success.

Have you ever been drawn to a product solely because of its packaging? Packaging is more than just a container; it's a powerful marketing tool that communicates brand identity, protects the product, and influences consumer decisions. Let's explore the intricate journey of packaging design and development from initial sketches to the store shelf.

At NorthnStar, we understand that effective packaging is crucial for product success. Many clients have approached us facing challenges in creating packaging that not only looks appealing but also meets practical requirements like protection, compliance, and cost-effectiveness. Recognizing these complexities, we've developed strategies to guide them through the packaging design process. This article delves into the stages of packaging development, sharing insights and experiences to help you navigate this vital aspect of product launch.

The Importance of Packaging Design

Packaging serves multiple purposes: it protects the product, provides information, and acts as a silent salesperson. Effective packaging can differentiate your product in a crowded marketplace, enhance brand recognition, and even influence purchasing decisions.

Why It Matters:

First Impressions: Packaging is often the first interaction a consumer has with a product.

Brand Communication: Conveys brand values, story, and identity.

Functionality: Protects the product during transportation and storage.

Regulatory Compliance: Meets legal requirements for labeling and safety.

Sustainability: Reflects environmental responsibility, which can influence consumer preferences.

Statistic:

According to Packaging World, 72% of consumers say that packaging design influences their purchasing decisions.

Case Study: Crafting Compelling Packaging for a Gourmet Food Product

Client Challenge:

A gourmet food company approached us with the goal of launching a new line of artisanal sauces. They faced several challenges:

Brand Differentiation: Standing out in a saturated market with numerous competitors.

Functional Requirements: Ensuring the packaging preserved product freshness and was easy to use.

Regulatory Compliance: Meeting food labeling regulations.

Cost Constraints: Developing premium packaging within budget.

Recognizing that packaging would play a critical role in their product's success, they sought our expertise to navigate the design and development process.

Our Approach:

We assembled a multidisciplinary team of packaging designers, engineers, and marketing strategists to address both the aesthetic and functional aspects of the packaging.

Actions Taken:

Market Research and Analysis:

Competitive Analysis: Studied competitors' packaging to identify gaps and opportunities.

Consumer Insights: Conducted surveys to understand consumer preferences and expectations.

Concept Development:

Sketching Ideas: Created initial design concepts that reflected the brand's artisanal and premium qualities.

Material Exploration: Evaluated different packaging materials such as glass, PET plastic, and biodegradable options.

Design Refinement:

3D Modeling: Developed detailed digital models to visualize the packaging.

Label and Branding Design: Crafted label designs that highlighted key product features and brand story.

User Experience Focus: Ensured the packaging was easy to open, handle, and reseal.

Prototyping and Testing:

Physical Prototypes: Produced prototypes to assess the look and feel.

Functionality Testing: Tested packaging for durability, leak prevention, and shelf-life preservation.

Consumer Feedback: Gathered input from focus groups to refine the design.

Regulatory Compliance:

Labeling Requirements: Ensured all mandatory information was correctly displayed (ingredients, nutritional information, allergen warnings).

Certification: Assisted with obtaining necessary certifications for food packaging.

Cost Optimization:

Material Selection: Chose cost-effective materials without compromising quality.

Supplier Negotiations: Worked with manufacturers to optimize production costs.

Outcome:

Distinctive Packaging: Created an eye-catching design that stood out on shelves and conveyed the brand's premium positioning.

Enhanced User Experience: The packaging was praised for its ease of use and functionality.

Regulatory Approval: Successfully met all compliance requirements, avoiding potential delays.

Market Success: The product launch was a success, with strong sales and positive consumer feedback attributing to the packaging design.

Brand Growth: The client established a strong market presence, leading to expansion into additional product lines.

Key Takeaways:

Holistic Approach: Integrating design, functionality, and compliance leads to effective packaging.

Consumer-Centric Design: Understanding the target audience enhances appeal and usability.

Material Considerations: Choosing the right materials balances aesthetics, functionality, and cost.

Iterative Process: Prototyping and testing are essential to refine the design.

Regulatory Awareness: Early attention to compliance prevents costly revisions and delays.

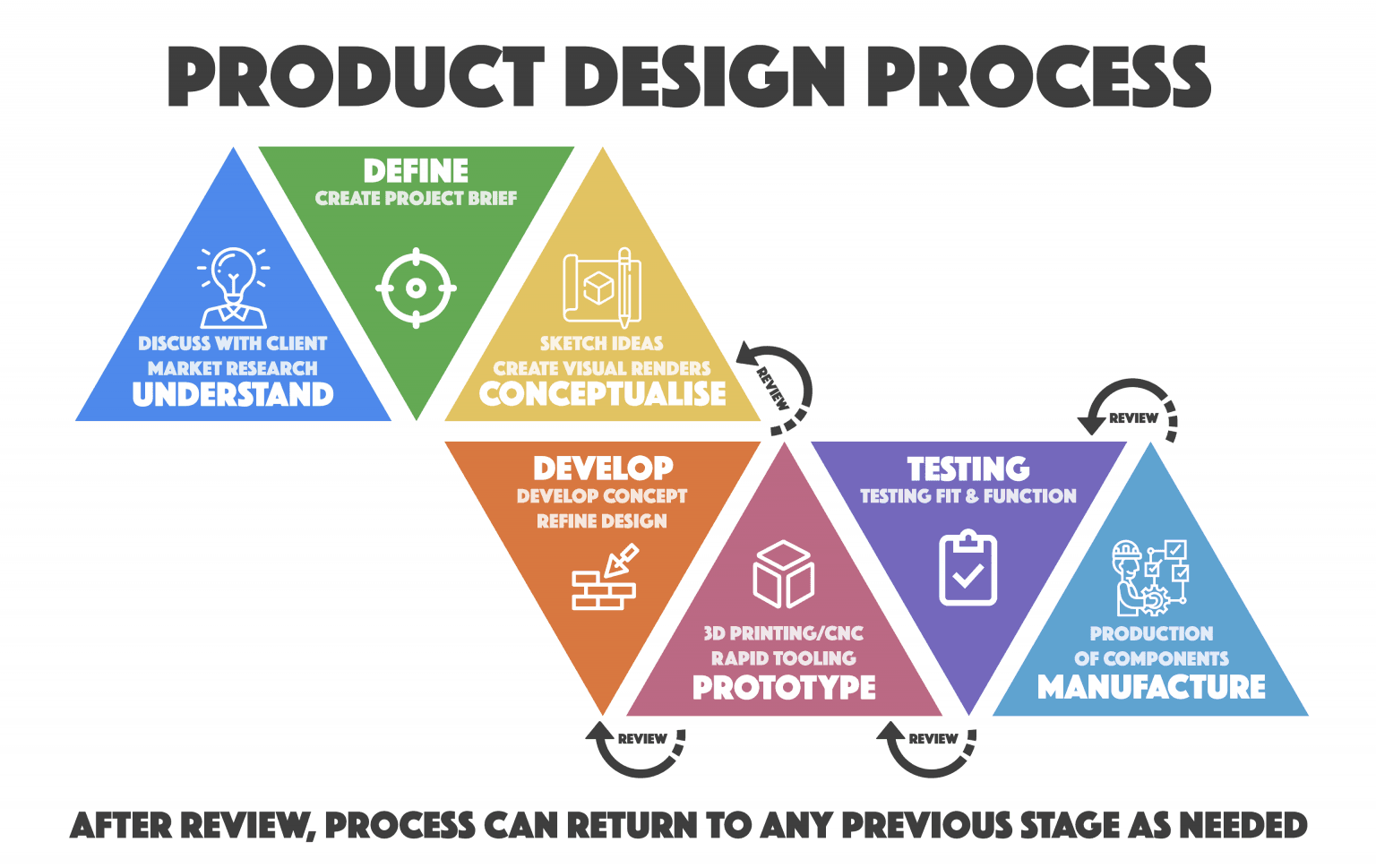

Stages of Packaging Design and Development

1. Research and Planning

Market Analysis: Understand industry trends and competitor packaging.

Target Audience Identification: Define who the packaging needs to appeal to.

Brand Alignment: Ensure packaging reflects brand values and messaging.

2. Conceptualization

Idea Generation: Brainstorm creative concepts and sketches.

Material Exploration: Consider various materials and their implications (cost, sustainability, functionality).

3. Design Development

Structural Design: Develop the shape and form of the packaging.

Graphic Design: Create visual elements including colors, typography, and imagery.

Functional Features: Incorporate elements like resealable closures, tamper-evidence, or dispensing mechanisms.

4. Prototyping and Testing

Mock-Ups: Produce prototypes to assess design and functionality.

Performance Testing: Evaluate durability, protection, and usability.

Consumer Testing: Gather feedback to refine the design.

5. Regulatory Compliance

Labeling Laws: Adhere to regulations regarding product information disclosure.

Safety Standards: Ensure packaging materials are safe for intended use.

Environmental Regulations: Consider recycling symbols and sustainability claims.

6. Production and Implementation

Supplier Selection: Choose reliable manufacturers and printers.

Quality Control: Establish standards and inspection protocols.

Logistics Planning: Coordinate packaging production with product manufacturing and distribution timelines.

Challenges in Packaging Design and Development

1. Balancing Aesthetics and Functionality

Challenge: Creating packaging that is both attractive and practical.

Solution: Collaborate closely between designers and engineers to ensure feasibility.

2. Cost Constraints

Challenge: Designing premium packaging within budget limitations.

Solution: Optimize material choices and manufacturing processes to reduce costs.

3. Sustainability

Challenge: Meeting consumer demand for eco-friendly packaging.

Solution: Explore sustainable materials and design for recyclability or reusability.

4. Regulatory Compliance

Challenge: Navigating complex regulations across different regions.

Solution: Engage regulatory experts early to ensure all requirements are met.

5. Supply Chain Coordination

Challenge: Synchronizing packaging production with product manufacturing.

Solution: Develop detailed timelines and maintain open communication with all stakeholders.

NorthnStar's Expertise in Packaging Design

At NorthnStar, we offer comprehensive packaging design and development services that cover every stage from initial concept to production.

Our Services Include:

Strategic Planning: Aligning packaging with brand and marketing objectives.

Creative Design: Crafting visually compelling and functional packaging.

Material Selection: Advising on materials that meet aesthetic, functional, and environmental goals.

Prototyping and Testing: Developing prototypes for evaluation and refinement.

Regulatory Compliance Support: Guiding clients through labeling and safety requirements.

Supplier Management: Assisting with manufacturer selection and coordination.

Cost Optimization: Identifying opportunities to reduce costs without sacrificing quality.

Client Success Story:

Our collaboration with the gourmet food company not only resolved their initial challenges but also contributed to their product's market success. By taking a holistic approach to packaging design, we helped them create a compelling and functional package that resonated with consumers and reinforced their brand identity.

Conclusion

Packaging is a critical component of product success, serving as both a protective vessel and a powerful marketing tool. By approaching packaging design and development thoughtfully and strategically, you can create packaging that enhances your product's appeal, meets practical requirements, and contributes to your brand's success.

At NorthnStar, we're passionate about transforming packaging from a necessity into a competitive advantage. Let us help you bring your packaging vision from sketch to shelf.

Ready to elevate your product with exceptional packaging design? Contact NorthnStar today, and let's embark on this journey together.

Have you ever been drawn to a product solely because of its packaging? Packaging is more than just a container; it's a powerful marketing tool that communicates brand identity, protects the product, and influences consumer decisions. Let's explore the intricate journey of packaging design and development from initial sketches to the store shelf.

At NorthnStar, we understand that effective packaging is crucial for product success. Many clients have approached us facing challenges in creating packaging that not only looks appealing but also meets practical requirements like protection, compliance, and cost-effectiveness. Recognizing these complexities, we've developed strategies to guide them through the packaging design process. This article delves into the stages of packaging development, sharing insights and experiences to help you navigate this vital aspect of product launch.

The Importance of Packaging Design

Packaging serves multiple purposes: it protects the product, provides information, and acts as a silent salesperson. Effective packaging can differentiate your product in a crowded marketplace, enhance brand recognition, and even influence purchasing decisions.

Why It Matters:

First Impressions: Packaging is often the first interaction a consumer has with a product.

Brand Communication: Conveys brand values, story, and identity.

Functionality: Protects the product during transportation and storage.

Regulatory Compliance: Meets legal requirements for labeling and safety.

Sustainability: Reflects environmental responsibility, which can influence consumer preferences.

Statistic:

According to Packaging World, 72% of consumers say that packaging design influences their purchasing decisions.

Case Study: Crafting Compelling Packaging for a Gourmet Food Product

Client Challenge:

A gourmet food company approached us with the goal of launching a new line of artisanal sauces. They faced several challenges:

Brand Differentiation: Standing out in a saturated market with numerous competitors.

Functional Requirements: Ensuring the packaging preserved product freshness and was easy to use.

Regulatory Compliance: Meeting food labeling regulations.

Cost Constraints: Developing premium packaging within budget.

Recognizing that packaging would play a critical role in their product's success, they sought our expertise to navigate the design and development process.

Our Approach:

We assembled a multidisciplinary team of packaging designers, engineers, and marketing strategists to address both the aesthetic and functional aspects of the packaging.

Actions Taken:

Market Research and Analysis:

Competitive Analysis: Studied competitors' packaging to identify gaps and opportunities.

Consumer Insights: Conducted surveys to understand consumer preferences and expectations.

Concept Development:

Sketching Ideas: Created initial design concepts that reflected the brand's artisanal and premium qualities.

Material Exploration: Evaluated different packaging materials such as glass, PET plastic, and biodegradable options.

Design Refinement:

3D Modeling: Developed detailed digital models to visualize the packaging.

Label and Branding Design: Crafted label designs that highlighted key product features and brand story.

User Experience Focus: Ensured the packaging was easy to open, handle, and reseal.

Prototyping and Testing:

Physical Prototypes: Produced prototypes to assess the look and feel.

Functionality Testing: Tested packaging for durability, leak prevention, and shelf-life preservation.

Consumer Feedback: Gathered input from focus groups to refine the design.

Regulatory Compliance:

Labeling Requirements: Ensured all mandatory information was correctly displayed (ingredients, nutritional information, allergen warnings).

Certification: Assisted with obtaining necessary certifications for food packaging.

Cost Optimization:

Material Selection: Chose cost-effective materials without compromising quality.

Supplier Negotiations: Worked with manufacturers to optimize production costs.

Outcome:

Distinctive Packaging: Created an eye-catching design that stood out on shelves and conveyed the brand's premium positioning.

Enhanced User Experience: The packaging was praised for its ease of use and functionality.

Regulatory Approval: Successfully met all compliance requirements, avoiding potential delays.

Market Success: The product launch was a success, with strong sales and positive consumer feedback attributing to the packaging design.

Brand Growth: The client established a strong market presence, leading to expansion into additional product lines.

Key Takeaways:

Holistic Approach: Integrating design, functionality, and compliance leads to effective packaging.

Consumer-Centric Design: Understanding the target audience enhances appeal and usability.

Material Considerations: Choosing the right materials balances aesthetics, functionality, and cost.

Iterative Process: Prototyping and testing are essential to refine the design.

Regulatory Awareness: Early attention to compliance prevents costly revisions and delays.

Stages of Packaging Design and Development

1. Research and Planning

Market Analysis: Understand industry trends and competitor packaging.

Target Audience Identification: Define who the packaging needs to appeal to.

Brand Alignment: Ensure packaging reflects brand values and messaging.

2. Conceptualization

Idea Generation: Brainstorm creative concepts and sketches.

Material Exploration: Consider various materials and their implications (cost, sustainability, functionality).

3. Design Development

Structural Design: Develop the shape and form of the packaging.

Graphic Design: Create visual elements including colors, typography, and imagery.

Functional Features: Incorporate elements like resealable closures, tamper-evidence, or dispensing mechanisms.

4. Prototyping and Testing

Mock-Ups: Produce prototypes to assess design and functionality.

Performance Testing: Evaluate durability, protection, and usability.

Consumer Testing: Gather feedback to refine the design.

5. Regulatory Compliance

Labeling Laws: Adhere to regulations regarding product information disclosure.

Safety Standards: Ensure packaging materials are safe for intended use.

Environmental Regulations: Consider recycling symbols and sustainability claims.

6. Production and Implementation

Supplier Selection: Choose reliable manufacturers and printers.

Quality Control: Establish standards and inspection protocols.

Logistics Planning: Coordinate packaging production with product manufacturing and distribution timelines.

Challenges in Packaging Design and Development

1. Balancing Aesthetics and Functionality

Challenge: Creating packaging that is both attractive and practical.

Solution: Collaborate closely between designers and engineers to ensure feasibility.

2. Cost Constraints

Challenge: Designing premium packaging within budget limitations.

Solution: Optimize material choices and manufacturing processes to reduce costs.

3. Sustainability

Challenge: Meeting consumer demand for eco-friendly packaging.

Solution: Explore sustainable materials and design for recyclability or reusability.

4. Regulatory Compliance

Challenge: Navigating complex regulations across different regions.

Solution: Engage regulatory experts early to ensure all requirements are met.

5. Supply Chain Coordination

Challenge: Synchronizing packaging production with product manufacturing.

Solution: Develop detailed timelines and maintain open communication with all stakeholders.

NorthnStar's Expertise in Packaging Design

At NorthnStar, we offer comprehensive packaging design and development services that cover every stage from initial concept to production.

Our Services Include:

Strategic Planning: Aligning packaging with brand and marketing objectives.

Creative Design: Crafting visually compelling and functional packaging.

Material Selection: Advising on materials that meet aesthetic, functional, and environmental goals.

Prototyping and Testing: Developing prototypes for evaluation and refinement.

Regulatory Compliance Support: Guiding clients through labeling and safety requirements.

Supplier Management: Assisting with manufacturer selection and coordination.

Cost Optimization: Identifying opportunities to reduce costs without sacrificing quality.

Client Success Story:

Our collaboration with the gourmet food company not only resolved their initial challenges but also contributed to their product's market success. By taking a holistic approach to packaging design, we helped them create a compelling and functional package that resonated with consumers and reinforced their brand identity.

Conclusion

Packaging is a critical component of product success, serving as both a protective vessel and a powerful marketing tool. By approaching packaging design and development thoughtfully and strategically, you can create packaging that enhances your product's appeal, meets practical requirements, and contributes to your brand's success.

At NorthnStar, we're passionate about transforming packaging from a necessity into a competitive advantage. Let us help you bring your packaging vision from sketch to shelf.

Ready to elevate your product with exceptional packaging design? Contact NorthnStar today, and let's embark on this journey together.

Explore the comprehensive process of packaging design and development, from initial concepts to final production. This article delves into real-world challenges, strategies, and best practices, highlighting NorthnStar's expertise in creating packaging that captivates consumers and enhances product success.

Have you ever been drawn to a product solely because of its packaging? Packaging is more than just a container; it's a powerful marketing tool that communicates brand identity, protects the product, and influences consumer decisions. Let's explore the intricate journey of packaging design and development from initial sketches to the store shelf.

At NorthnStar, we understand that effective packaging is crucial for product success. Many clients have approached us facing challenges in creating packaging that not only looks appealing but also meets practical requirements like protection, compliance, and cost-effectiveness. Recognizing these complexities, we've developed strategies to guide them through the packaging design process. This article delves into the stages of packaging development, sharing insights and experiences to help you navigate this vital aspect of product launch.

The Importance of Packaging Design

Packaging serves multiple purposes: it protects the product, provides information, and acts as a silent salesperson. Effective packaging can differentiate your product in a crowded marketplace, enhance brand recognition, and even influence purchasing decisions.

Why It Matters:

First Impressions: Packaging is often the first interaction a consumer has with a product.

Brand Communication: Conveys brand values, story, and identity.

Functionality: Protects the product during transportation and storage.

Regulatory Compliance: Meets legal requirements for labeling and safety.

Sustainability: Reflects environmental responsibility, which can influence consumer preferences.

Statistic:

According to Packaging World, 72% of consumers say that packaging design influences their purchasing decisions.

Case Study: Crafting Compelling Packaging for a Gourmet Food Product

Client Challenge:

A gourmet food company approached us with the goal of launching a new line of artisanal sauces. They faced several challenges:

Brand Differentiation: Standing out in a saturated market with numerous competitors.

Functional Requirements: Ensuring the packaging preserved product freshness and was easy to use.

Regulatory Compliance: Meeting food labeling regulations.

Cost Constraints: Developing premium packaging within budget.

Recognizing that packaging would play a critical role in their product's success, they sought our expertise to navigate the design and development process.

Our Approach:

We assembled a multidisciplinary team of packaging designers, engineers, and marketing strategists to address both the aesthetic and functional aspects of the packaging.

Actions Taken:

Market Research and Analysis:

Competitive Analysis: Studied competitors' packaging to identify gaps and opportunities.

Consumer Insights: Conducted surveys to understand consumer preferences and expectations.

Concept Development:

Sketching Ideas: Created initial design concepts that reflected the brand's artisanal and premium qualities.

Material Exploration: Evaluated different packaging materials such as glass, PET plastic, and biodegradable options.

Design Refinement:

3D Modeling: Developed detailed digital models to visualize the packaging.

Label and Branding Design: Crafted label designs that highlighted key product features and brand story.

User Experience Focus: Ensured the packaging was easy to open, handle, and reseal.

Prototyping and Testing:

Physical Prototypes: Produced prototypes to assess the look and feel.

Functionality Testing: Tested packaging for durability, leak prevention, and shelf-life preservation.

Consumer Feedback: Gathered input from focus groups to refine the design.

Regulatory Compliance:

Labeling Requirements: Ensured all mandatory information was correctly displayed (ingredients, nutritional information, allergen warnings).

Certification: Assisted with obtaining necessary certifications for food packaging.

Cost Optimization:

Material Selection: Chose cost-effective materials without compromising quality.

Supplier Negotiations: Worked with manufacturers to optimize production costs.

Outcome:

Distinctive Packaging: Created an eye-catching design that stood out on shelves and conveyed the brand's premium positioning.

Enhanced User Experience: The packaging was praised for its ease of use and functionality.

Regulatory Approval: Successfully met all compliance requirements, avoiding potential delays.

Market Success: The product launch was a success, with strong sales and positive consumer feedback attributing to the packaging design.

Brand Growth: The client established a strong market presence, leading to expansion into additional product lines.

Key Takeaways:

Holistic Approach: Integrating design, functionality, and compliance leads to effective packaging.

Consumer-Centric Design: Understanding the target audience enhances appeal and usability.

Material Considerations: Choosing the right materials balances aesthetics, functionality, and cost.

Iterative Process: Prototyping and testing are essential to refine the design.

Regulatory Awareness: Early attention to compliance prevents costly revisions and delays.

Stages of Packaging Design and Development

1. Research and Planning

Market Analysis: Understand industry trends and competitor packaging.

Target Audience Identification: Define who the packaging needs to appeal to.

Brand Alignment: Ensure packaging reflects brand values and messaging.

2. Conceptualization

Idea Generation: Brainstorm creative concepts and sketches.

Material Exploration: Consider various materials and their implications (cost, sustainability, functionality).

3. Design Development

Structural Design: Develop the shape and form of the packaging.

Graphic Design: Create visual elements including colors, typography, and imagery.

Functional Features: Incorporate elements like resealable closures, tamper-evidence, or dispensing mechanisms.

4. Prototyping and Testing

Mock-Ups: Produce prototypes to assess design and functionality.

Performance Testing: Evaluate durability, protection, and usability.

Consumer Testing: Gather feedback to refine the design.

5. Regulatory Compliance

Labeling Laws: Adhere to regulations regarding product information disclosure.

Safety Standards: Ensure packaging materials are safe for intended use.

Environmental Regulations: Consider recycling symbols and sustainability claims.

6. Production and Implementation

Supplier Selection: Choose reliable manufacturers and printers.

Quality Control: Establish standards and inspection protocols.

Logistics Planning: Coordinate packaging production with product manufacturing and distribution timelines.

Challenges in Packaging Design and Development

1. Balancing Aesthetics and Functionality

Challenge: Creating packaging that is both attractive and practical.

Solution: Collaborate closely between designers and engineers to ensure feasibility.

2. Cost Constraints

Challenge: Designing premium packaging within budget limitations.

Solution: Optimize material choices and manufacturing processes to reduce costs.

3. Sustainability

Challenge: Meeting consumer demand for eco-friendly packaging.

Solution: Explore sustainable materials and design for recyclability or reusability.

4. Regulatory Compliance

Challenge: Navigating complex regulations across different regions.

Solution: Engage regulatory experts early to ensure all requirements are met.

5. Supply Chain Coordination

Challenge: Synchronizing packaging production with product manufacturing.

Solution: Develop detailed timelines and maintain open communication with all stakeholders.

NorthnStar's Expertise in Packaging Design

At NorthnStar, we offer comprehensive packaging design and development services that cover every stage from initial concept to production.

Our Services Include:

Strategic Planning: Aligning packaging with brand and marketing objectives.

Creative Design: Crafting visually compelling and functional packaging.

Material Selection: Advising on materials that meet aesthetic, functional, and environmental goals.

Prototyping and Testing: Developing prototypes for evaluation and refinement.

Regulatory Compliance Support: Guiding clients through labeling and safety requirements.

Supplier Management: Assisting with manufacturer selection and coordination.

Cost Optimization: Identifying opportunities to reduce costs without sacrificing quality.

Client Success Story:

Our collaboration with the gourmet food company not only resolved their initial challenges but also contributed to their product's market success. By taking a holistic approach to packaging design, we helped them create a compelling and functional package that resonated with consumers and reinforced their brand identity.

Conclusion

Packaging is a critical component of product success, serving as both a protective vessel and a powerful marketing tool. By approaching packaging design and development thoughtfully and strategically, you can create packaging that enhances your product's appeal, meets practical requirements, and contributes to your brand's success.

At NorthnStar, we're passionate about transforming packaging from a necessity into a competitive advantage. Let us help you bring your packaging vision from sketch to shelf.

Ready to elevate your product with exceptional packaging design? Contact NorthnStar today, and let's embark on this journey together.

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses

Other Blogs

Other Blogs

Check our other project Blogs with useful insight and information for your businesses